Use Case: Ceramic Tile Lines

Tackling Downtime And Contamination

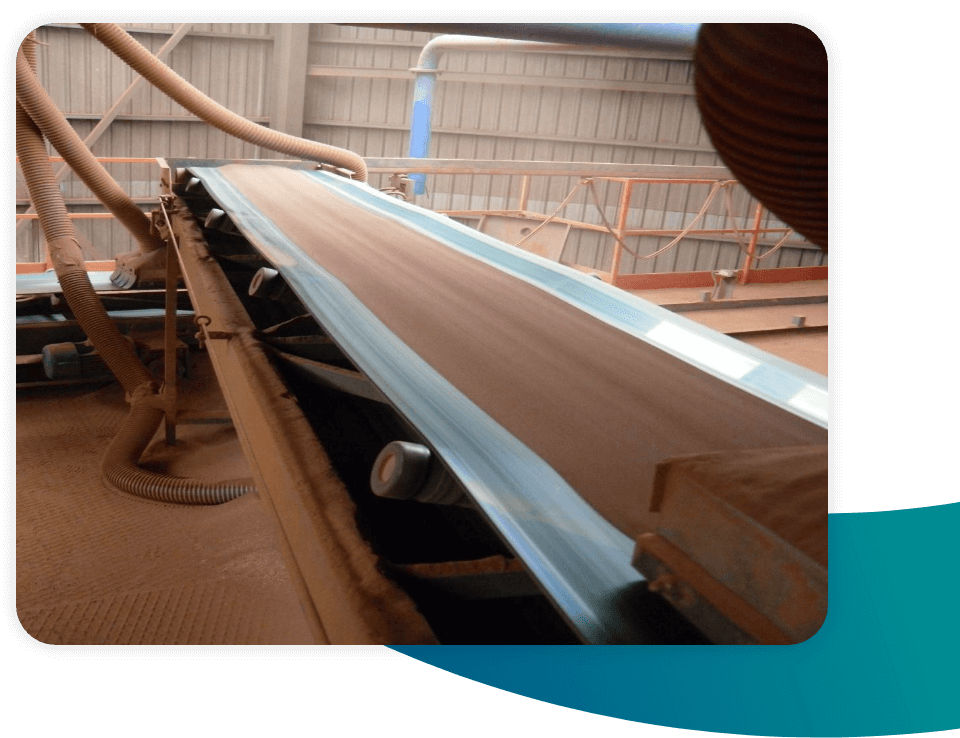

Challenge

The use of highly abrasive materials in the production process presents a significant challenge. Traditional rubber belts release belt particles that contaminate the powders and clay used in the production of ceramic and roof tiles and result in post-production rejects.

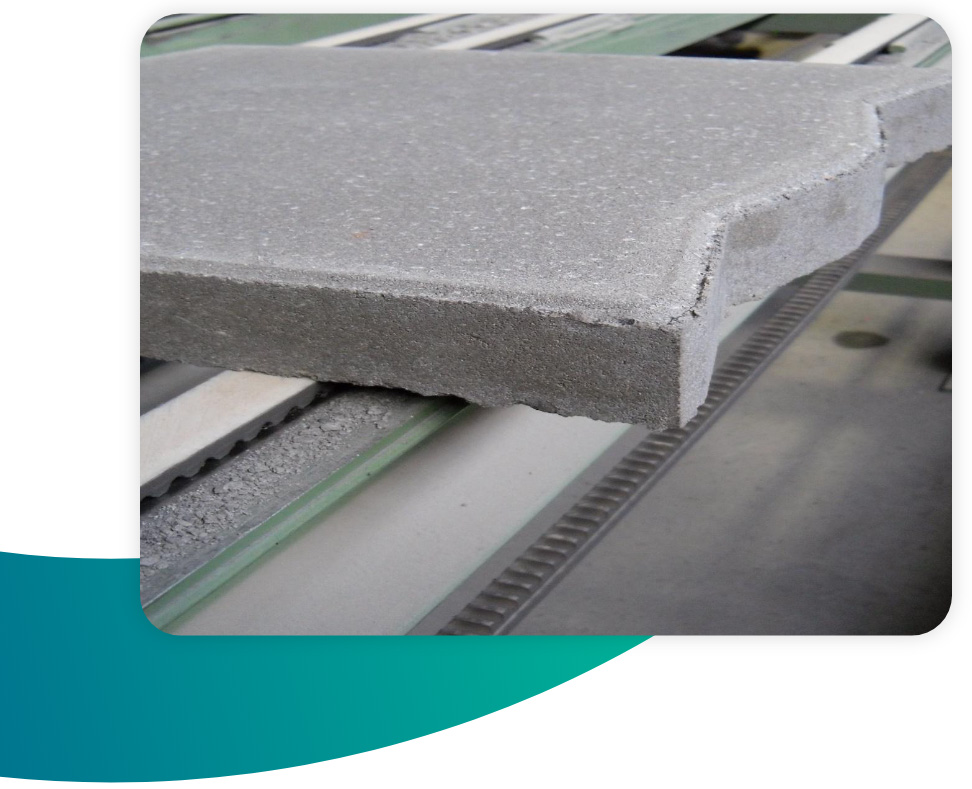

Solution

Volta’s durable profile and flat belts are dense and stable with little or no release of contaminants into pre-processed raw materials. Powders are cleaner and factories report reduced reject levels from 5-8% to below 1%.

Results

Reduced electric consumption and maintenance time resulting from replacing low-cost rubber belting.