Home » Solutions By conveyor type » Horizontal Conveyors

Horizontal conveyors are the most basic and widely used conveyor style in the market. They are used on assembly lines, small parts handling, food processing and integrated inside more sophisticated machinery to give increased throughput. They have fewer limitations than other conveyor types in terms of dimensions, speeds, load, and space required. They can be suited to accumulation or telescopic applications. Much of the same can be said for simple two-axle conveyors when used on a slight incline. They can function well depending on the angle, product type and flow rate.

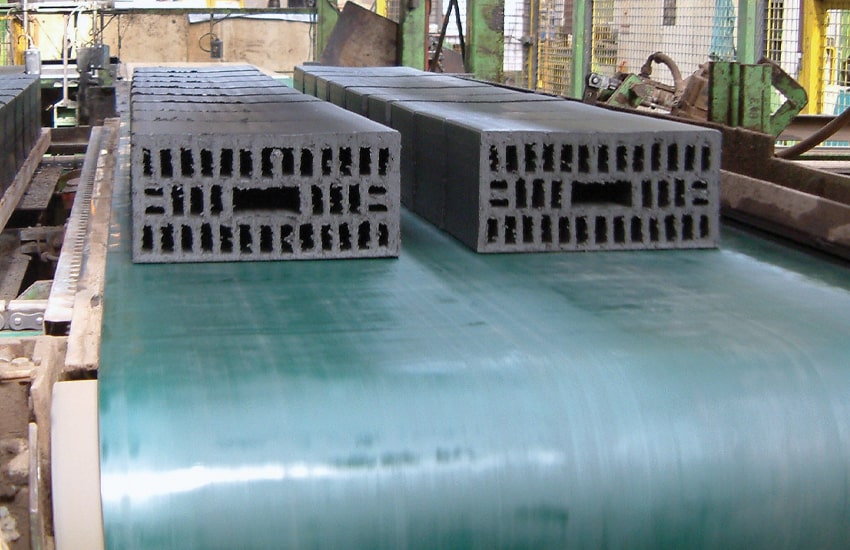

The belt path on a horizontal conveyor is simple; typically, a straight-line center to center bed with the belt wrapped around two pulleys. Some applications may dictate additional rollers or features. Heavy wear and tear can result from incorrect conveyor design and belt selection.

The capacity of the conveyor must be taken into consideration making sure the product is contained and does not fall under and inside the belt path.

A conventional belt running without a product can fail from off-tracking or splice failure. Volta Positive Drive belts permit the design of more compact and cost-effective conveyors with added benefits of self-tracking and the elimination of slipping on rollers. Volta belts save downtime and offer lower maintenance costs while creating a hygienic and cleanable working environment for food processing conveyors. Long-lasting and invisible welded joints can save multiple belt changeovers. On flat belts, adding guides can provide tracking that will not detach from the strain of flexing around pulleys.

When you are looking for the ideal solution to help you increase your production rate, simplify the process, slash costs and comply with regulations, it’s time for SuperDrive™!

A Positive Drive belt that solves the key mechanical problems of classic flat belts, namely, slipping and off-tracking, SuperDrive™ helps lower running costs for reduced cost of ownership, requires less hot water, provides less chemical exposure, and reduces cleaning time.

As a result, you have more time and money for production. Perfect!

Dough pump conveyors are used to process raw dough in large-scale production bakeries.

These conveyors elevate dough at a sharp incline and commonly use plied belts with bottom guides. Due to uneven loads, bakery belts often suffer from off-tracking, and slippage, which can cause fraying, tearing and the need for belt tension, leading to belt failure. A retrofit to

SuperDrive™ solves all of that, making raw dough production… as easy as pie.

Bakery lines often incorporate small pulley diameters and static ‘knife edge’ nose bars. When selecting the right belt for your business, make sure to measure the diameter/radius and, to note the wrapping angle.

Our bakery conveyor belts are specifically tailored for biscuit and pizza base cutting lines, helping make dough production simple and efficient.

Our TPE bakery conveyor belts are highly resistant to cuts and abrasion.

They are also easily repaired in the event of mechanical damage, making them robust, cost-effective, and literally, the best thing since sliced bread.