“Global Organizations of food safety have emerged due to legal and commercial pressure from consumer action as a result of food-safety scandals. Food safety audits check management systems, provide certification, assess the condition of the premises and products as well as confirm legal compliance.

The audit procedure includes a site inspection with a visual assessment of the entire manufacturing process.

The formal auditing process was first developed by the British Retail Consortium (BRC) in 1996 in order for retailers to share and cooperate. The standards were principally driven by the need to meet legal requirements. They assisted retailers (mainly supermarket chains) in fulfilling them, but they are also a key element in protecting consumer health. Retailers are legally obligated to take all reasonable precautions and to exercise due diligence to avoid problems. This includes the need for periodic verification of procedures and standards of hygiene at production facilities.

The increasing globalization of food supplies heightened the need for internationally accepted standards and led to the creation of the Global Food Safety Initiative (GFSI) in 2000. By incorporating local systems into the GFSI (e.g. BRC,IFS, FFSC 2200, SFQ) suppliers can conduct a single audit and thereby attain approval for multiple retail customers. Food safety processes are benchmarked which gives credibility and a guarantee to customers that the certified level of food safety and quality is provided, regardless of source.”

We ask you to take a couple of minutes to read the above text. We are certain this will explain the subject of auditing and why your production processes are increasingly being subjected to meet these procedures. Once this trend is understood, self-realization is critical because auditors are trained to follow industry standards and these standards are becoming stricter each year. The check on hygiene levels in food factories are becoming unyielding as well. Volta is the world’s leading producer and designer of the hygienic conveyor belt. The material we produce is homogeneous and apart from

conforming to auditing requirements, it is also economic to install and operate.

Let us pose a question; Have you had belts marked as a weak point in a recent audit? If you have had this problem, whether the belt type you are currently using is fabric (ply) belts or modular, Volta material is the best solution for retrofitting a hygienic upgrade on most food conveyors.

If you have not had any such problems; can you afford to be complacent and ignore this subject knowing that the next audit could end up requiring a change? Why wait for that to happen? Be Pro-active. Think of being given a negative audit and not even knowing how to choose the right type of retrofitting and the right belt type to reduce costs. The extra cost of investments made quickly and under pressure often means having to do things twice. Choose preventive maintenance and try Volta’s state of the art technology now. Give your QA team and your maintenance staff time to learn to work with this technology. You will profit by saving up to 50% of cleaning costs, water and downtime as well as improving bacteria counts and product shelf-life.

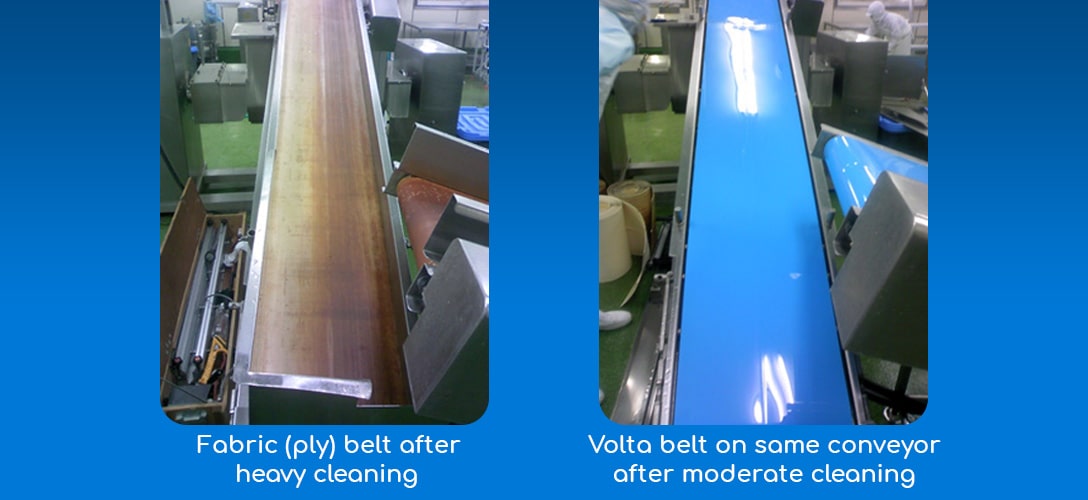

The fabric and modular belts we retrofitted in the above photos were both certified as ‘food grade’. Food grade is no longer enough; performance counts not certification. Volta believes that ‘extended belt performance’ means ‘extended hygienic belt performance’.