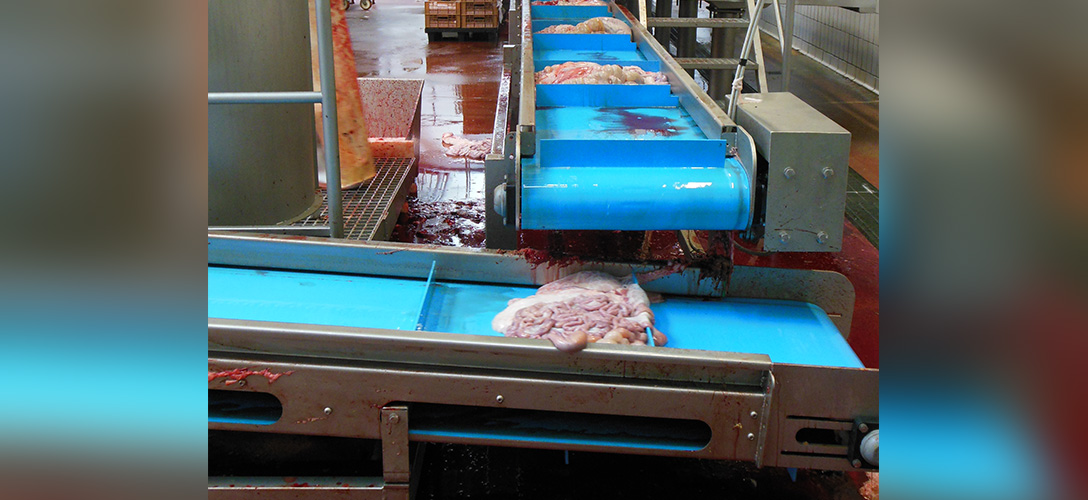

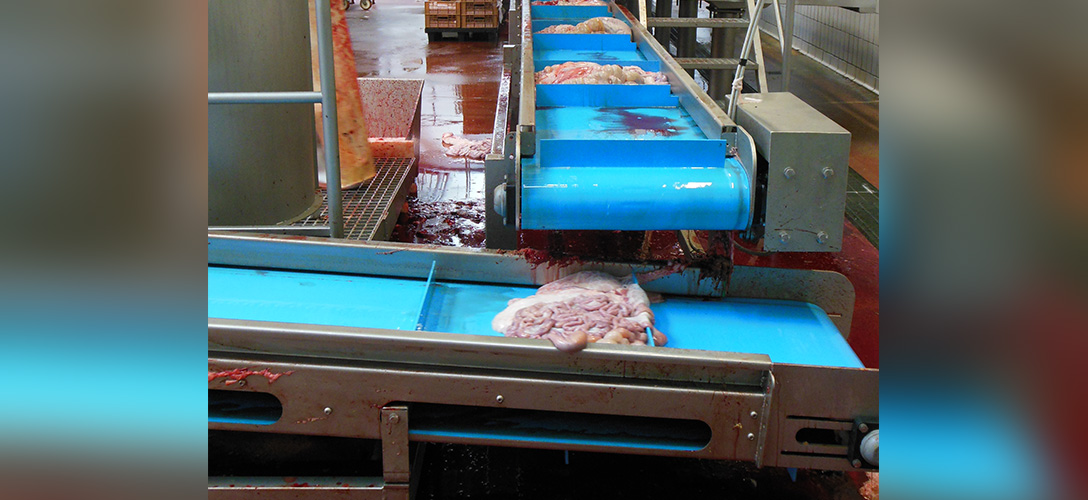

A newly equipped pork abattoir commissioned a set of conveyors designed with two flat belts that transferred offal at 90 degrees on a corner. The belts used synchronized compartments comprising of full width cleats, to keep each set of organs separate until the veterinary service on site had confirmed the meat as fit for consumption.