We are excited to announce our participation in Expo Carnes y Lácteos 2025, the premier event for the meat and dairy industries, taking place in Monterrey, N.L., Mexico from March 4-6, 2025.

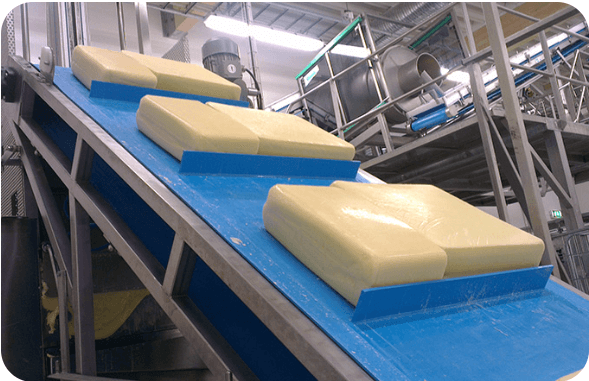

As a leader in the conveyor belt industry, we are proud to showcase our innovative solutions that are designed to optimize efficiency, food safety, and product quality in meat and dairy processing.

At the exhibition, our team of experts, Jonatan Pozorski and Carlos García, will be on hand to discuss how our high-quality, durable conveyor belts can streamline your operations. Whether you are looking for hygienic solutions, enhanced performance, or customized designs, Volta Belting offers the right products to meet your specific needs.

Why Choose Volta Belting for Your Meat and Dairy Conveyor Systems?

- Food Safety: Our conveyor belts are designed to meet the highest hygiene standards for the food industry.

- Durability: Built to withstand the demands of meat and dairy processing, ensuring long-lasting performance.

- Customization: Tailored solutions to fit your unique processing requirements.

Join Us at Expo Carnes y Lácteos 2025!

Date: March 4-6, 2025

Location: Cinter, Monterrey, N.L., Mexico

Booth Number: N:838

Schedule a Meeting with Our Experts Today!

Click below to learn more about how Volta Belting can enhance your operations.

Learn More About Our Meat Processing Solutions

Discover Our Dairy Processing Conveyor Belts

We look forward to seeing you there and discussing how Volta Belting can contribute to your success!