Home » Food-Grade Belts

Food Grade Belts

Foods are sourced from around the globe and while multinational and national brands advertise to influence purchasing habits, they are also responsible for making their products safe for consumption. Food grade belts can play a significant role in eliminating risks. Conveyor belting is one of the few plastic items permitted in direct contact with food and they are typically used for hours at a time without cleaning and with possible exposure to dangerous pathogens. Better than any other style of conveyor belt, Food grade thermoplastic belts are the only true monolithic plastic product that promotes improved hygienic conditions lowering bacteria counts resulting in more sanitary food products.

Food and Hygiene

Our Mission

Our mission is to offer hygienic food grade belts as alternatives to conventional fabric (plied) and modular belts. These belts are now seen by pioneering organizations such as EHEDG, as unhygienic as well as inferior in terms of costs of ownership. Used correctly, Volta food grade conveyor belts save both cost of ownership and improve food hygiene.

Solutions

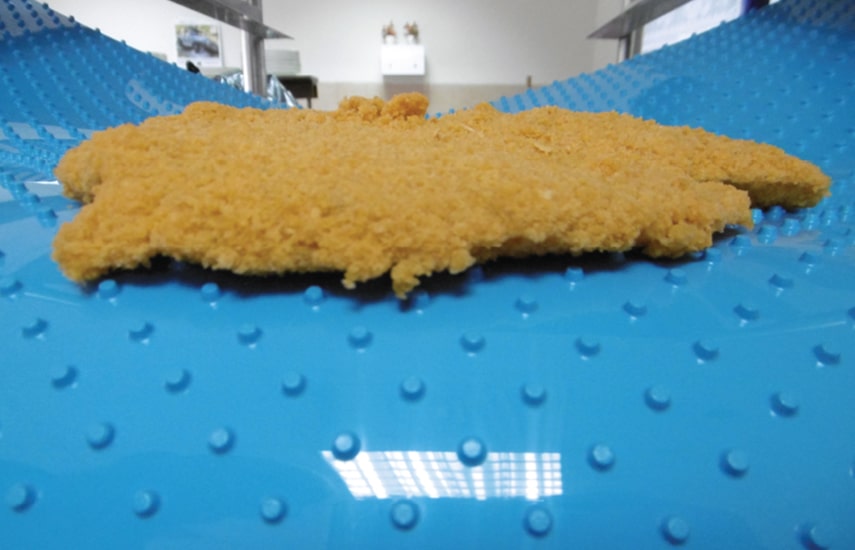

Volta food grade belts are made from solid thermoplastic extrusions; this in contrast with weak, unhygienic PU and PVC belts which incorporate fabric (plied) layers. Volta does offer options with different textures and colours but essentially, belt selection is mainly based on the conveyor construction and its characteristics with product load and temperature factored in. Our solutions and applications are determined by an in-depth understanding of both the requirements of the food grade conveyors and the physical forces needed to optimize the work of a conveyor belt in a processing system, regardless of the specific food product.

Conveyors

Applications

Gallery

Food processing exists in all levels from simple washing and packing to ready-made meals. Volta Belting has decades of experience in advising all sectors of the food industry on hygienic conveyor belting. Further illustration of the gamut of products handled on our thermoplastic belting material can be found in our by-industry applications section. We show here a cross-section of both flat food belts in conjunction with conveyor systems.

Are you looking for a solution?

Learn from our experience

A common failure of many plastics used in conveyor belt comes from chemical attack of the belt compound. Most chemical exposure comes from plant cleaning operations.

A leading European producer of poultry sausages and smallgoods uses Volta extensively on over 50 conveyors.

Stainless steel boning and trimming belts with a non-food grade black rubber V-guides are still in use in the meat industry. These guides produce a black powder that eventually migrates to the surface requiring intermittent costly wash downs.