When you think of a meat processing plant, what comes to mind? Most likely, it’s a complex, high-paced environment where every detail counts. From the moment the animals are slaughtered to when the final product is packed for distribution, every step in the meat production process requires precision, hygiene, and efficiency. Amid all of the heavy machinery and specialized equipment, there’s one unsung hero that is often over-looked – the conveyor belt.

While it might seem like just a basic transportation system, selecting the proper conveyor belts in meat processing plants can actually be a game changer. They not only streamline operations but also significantly impact hygiene, safety, and overall productivity. Let’s dive into why conveyor belts are so crucial to modern meat processing plants and how they’re transforming the industry.

Boosting Efficiency and Speed

One of the primary reasons conveyor belts are a game changer is their ability to dramatically increase the speed and efficiency of meat processing.

In a processing plant, time is money. Meat products need to move from one station to the next quickly and any delays in the flow of goods can create bottlenecks, slow down production, reducing through-put.

Hygiene Standards

In the meat processing industry, hygiene is paramount. The presence of blood, fat, and bones in the processing environment creates a constant risk of contamination, which can affect both the product and the safety of the facility. To address this, there are food-grade conveyor belts that are specifically designed to minimize these risks. They provide superior cleanliness and resistance to bacterial growth.

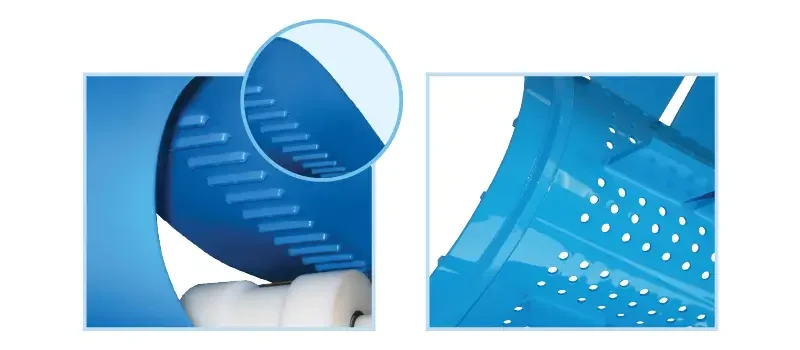

Volta Food Grade Conveyor Belts

are made from dense, extruded material that contains no fabric, eliminating the risk of fraying or absorbing fluids. This non-porous design ensures that the belts do not absorb fats, liquids, or chemicals which make them highly resistant to contamination. The smooth surface of these belts is a key feature, as it is less likely to trap bacteria, fats, or debris. This not only helps maintain a cleaner environment but also ensures that harmful microorganisms are not harbored on the belt’s surface. This reduces the risk of contamination during processing.

These belts are impervious to the fats, liquids, and chemicals typically found in meat processing and their durability ensures that they can withstand frequent washdowns without degrading over time.

Different Stages of Processing

Conveyor belts are transforming meat processing plants in other ways as well. The Belts various compounds and styles, have the ability to adapt to different stages of production, whether it’s deboning, cutting, jointing, or packaging. Each stage of a meat processing line requires specific handling methods. Volta’s SuperDrive™ is suited to most heavy-duty meat processing applications. The thicker harder compound choices can cope with high impact and heavy accumulation.

For example:

A) Slaughterhouse Lines/Boning and De-Boning Lines

The belts meet the most demanding challenges in the meat processing industry. They can be used on boning lines where high impact and heavy wear and tear are commonplace. They outperform modular belts where parts are replaced frequently and provide superior hygiene.

B) Primary Processing Lines

Volta’s belts are highly resistant to cut and abrasion. The belt will maintain low bacteria counts and require less maintenance and cleaning than any other belt on the market.

Reducing Downtime and Maintenance Costs

Conveyor systems are not only about moving meat products from one station to another; they are also designed for longevity and minimal downtime. The durability of modern conveyor belts means they require fewer repairs and replacements compared to older systems. Volta SuperDrive™ belts, are resistant to wear and tear, even under heavy loads. This resistance to degradation means less time spent on maintenance and fewer costly repairs.

Supporting Sustainable Efforts

Sustainability is becoming an increasingly important focus for industries across the globe and meat processing is no exception. Conveyor belts contribute to sustainability efforts by reducing waste and optimizing water and energy usage. Volta belts are durable, minimize water consumption, reduce the use of cleaning chemicals, and help save energy costs.

Conclusion

In the ever-evolving world of meat processing, conveyor belts are no longer just a convenience—they are a game changer. By increasing efficiency, improving hygiene, and reducing downtime, conveyor belts are playing a pivotal role in shaping the future of the industry.

Volta Belting transforms the fundamental challenges of meat processing into opportunities for reduced costs, enhanced product quality, and increased profitability.

To learn more about how advanced conveyor solutions can transform your meat processing operations, contact us today!