Home » Solutions by application type » Special Endless Applications

Reliable thermo-welded construction coupled with TPE flexibility and endless cords or fabric reinforcement produces customized solutions as Poly-V, V or Flat belts.

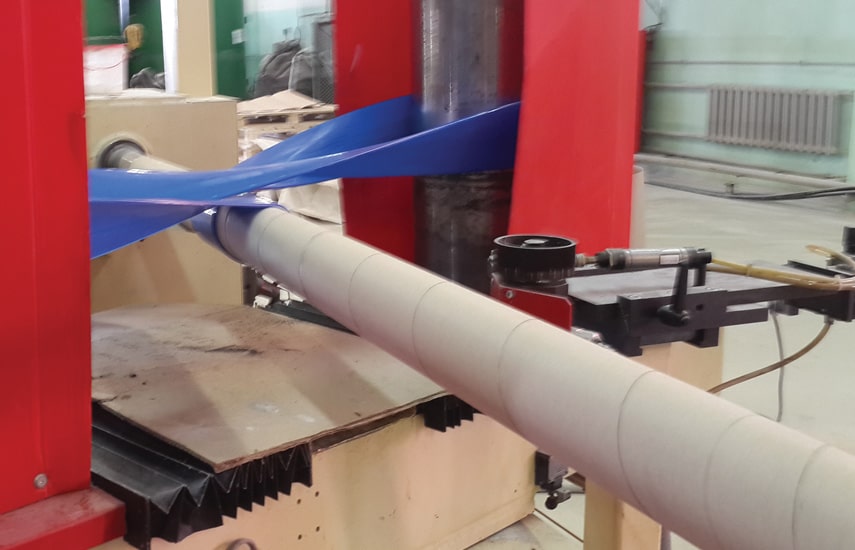

Tube winding belts

Food grade and non-food grade belts for all tube winding machines with pre-twist options can be produced for improved performance. Our tube winding belts replace thicker rubber belts and retain their grip better than textured PVC versions, without stretching or breaking.

Tuna compression belts

Used on dedicated machinery in the fish canning industry, they provide extended life and are used mainly for tuna and other large fish sea products. The belts are constructed from food grade flat materials with an option for a timing belt bottom side. Textured and smooth versions are available.

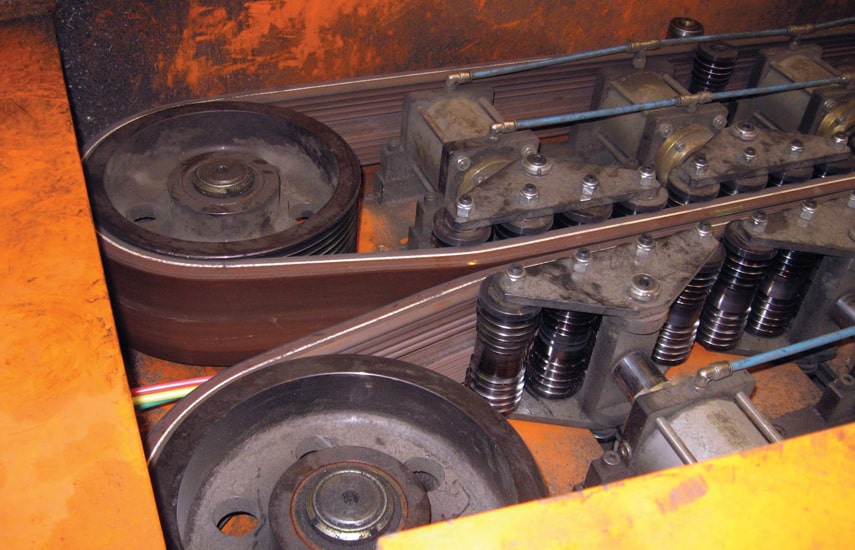

Haul Off/Caterpillar Belts

Flat, toothed and poly-V versions for plastic extrusion machines and cable production are available. Replacing fast wearing heavy duty rubber versions with thinner longer-lasting TPU materials can reduce wear and tear on bearings and motors. Layers can be varied to provide different grips and to fine-tune cushioning effects.

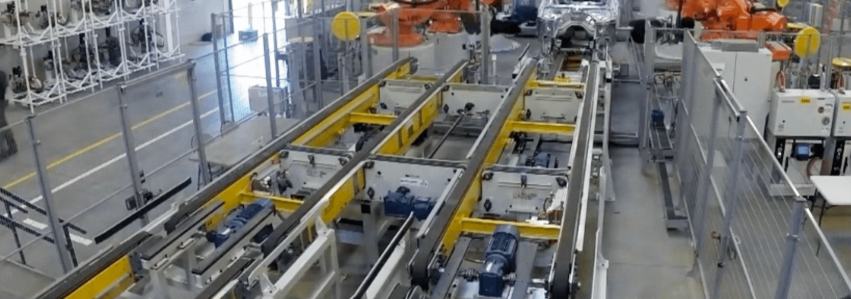

Volta accepted a challenge of developing a narrow composite belt that carries car chassis through an assembly line, past consecutive workstations. Belts were designed for a system 25 metres between axles and 55mm wide. These belts transport loads in excess of 4 tons (10500 lbs). Wider belts enable even heavier loads to be carried.

The belts do not elongate and have no joint. They are wear and paint-resistant, making them the perfect choice for an industrial setting where break downs would require a prolonged and expensive shutdown. With the old-style belt, partly assembled cars would be required to be removed during the changeover. The cars would have to be replaced on the line costing extending down time before they could continue production.

When you are looking for the ideal solution to help you increase your production rate, simplify the process, slash costs and comply with regulations, it’s time for SuperDrive™!

A Positive Drive belt that solves the key mechanical problems of classic flat belts, namely, slipping and off-tracking, SuperDrive™ helps lower running costs for reduced cost of ownership, requires less hot water, provides less chemical exposure, and reduces cleaning time.

As a result, you have more time and money for production. Perfect!

Dough pump conveyors are used to process raw dough in large-scale production bakeries.

These conveyors elevate dough at a sharp incline and commonly use plied belts with bottom guides. Due to uneven loads, bakery belts often suffer from off-tracking, and slippage, which can cause fraying, tearing and the need for belt tension, leading to belt failure. A retrofit to

SuperDrive™ solves all of that, making raw dough production… as easy as pie.

Bakery lines often incorporate small pulley diameters and static ‘knife edge’ nose bars. When selecting the right belt for your business, make sure to measure the diameter/radius and, to note the wrapping angle.

Our bakery conveyor belts are specifically tailored for biscuit and pizza base cutting lines, helping make dough production simple and efficient.

Our TPE bakery conveyor belts are highly resistant to cuts and abrasion.

They are also easily repaired in the event of mechanical damage, making them robust, cost-effective, and literally, the best thing since sliced bread.