Home » 溶接および加工ツール

Voltaは、独立したVoltaの顧客が市場に近い場所で材料を溶接・加工するためのツールを製造している。これを提供するサービスの重要な部分と見なしており、顧客がリードタイムにより迅速に対応できるようにし、この優れた技術を活用して自らを発展させる力を与えている。

すべてのツールには操作説明書が付属しており、Voltaの加工センター、ユーザーの施設、またはインターネットを通じてトレーニングが提供される。

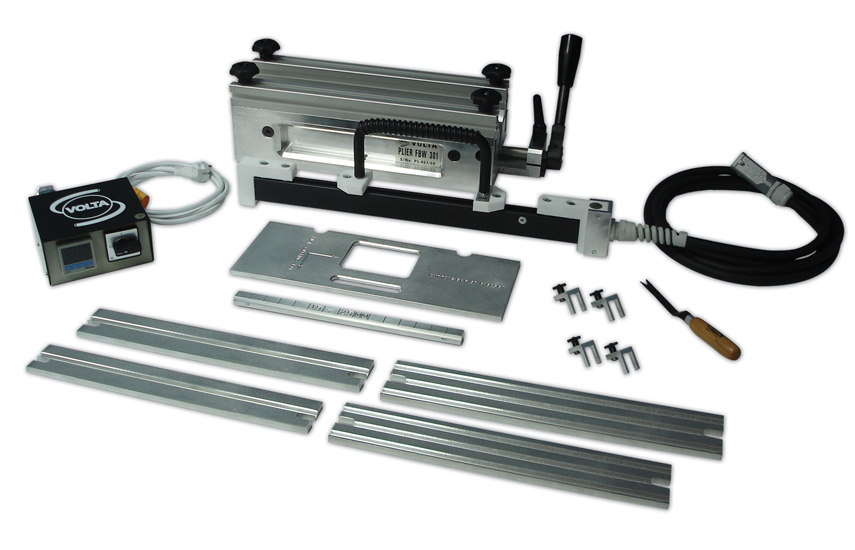

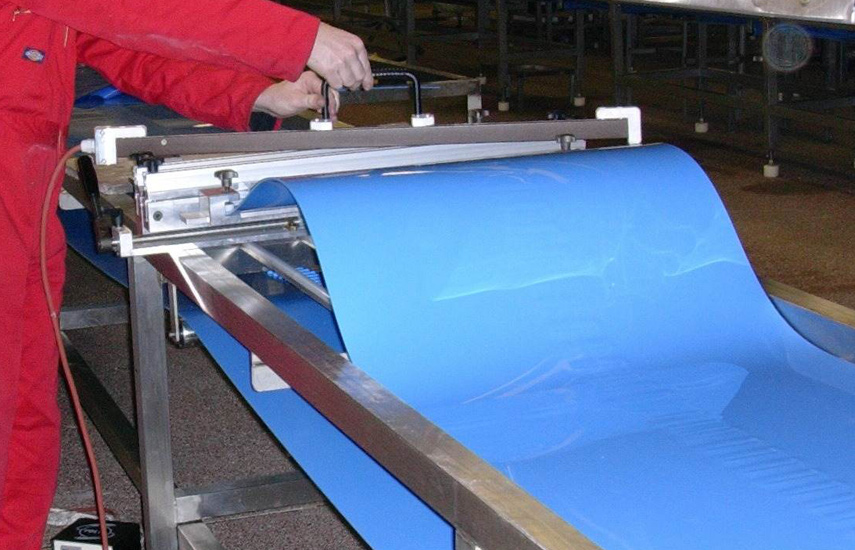

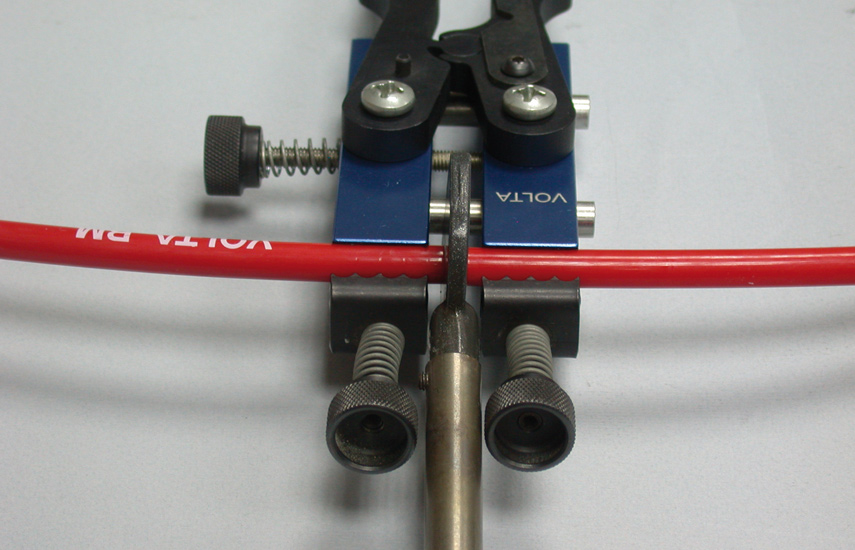

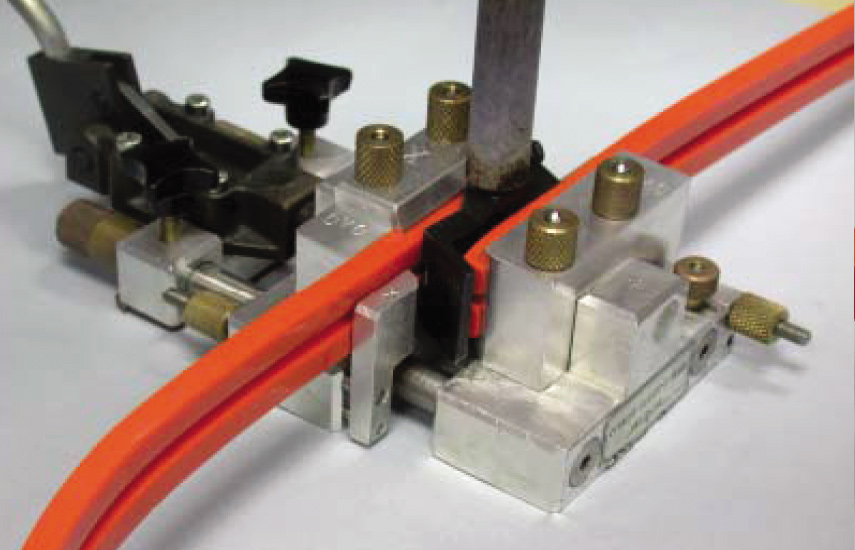

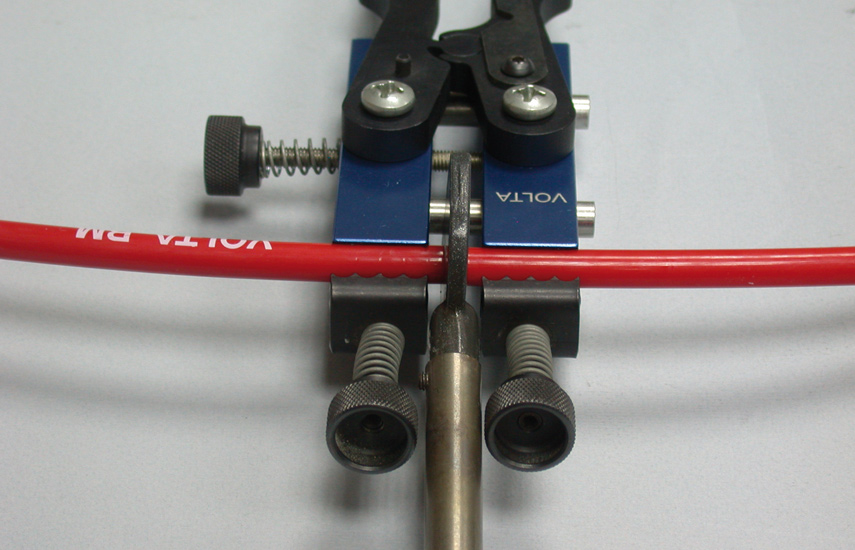

300mmから2000mmまでのフラットおよびポジティブドライブベルトのベルトスプライシングが可能である。FBWおよびPDWというコードのジグは現場に持ち込むことができ、単相電源のみで動作し、数分で溶接を行うことができるため、生産性が向上する。介入と人手が減少することで、外部サービスのスタッフと従業員の両方にとって、安全性が向上する。

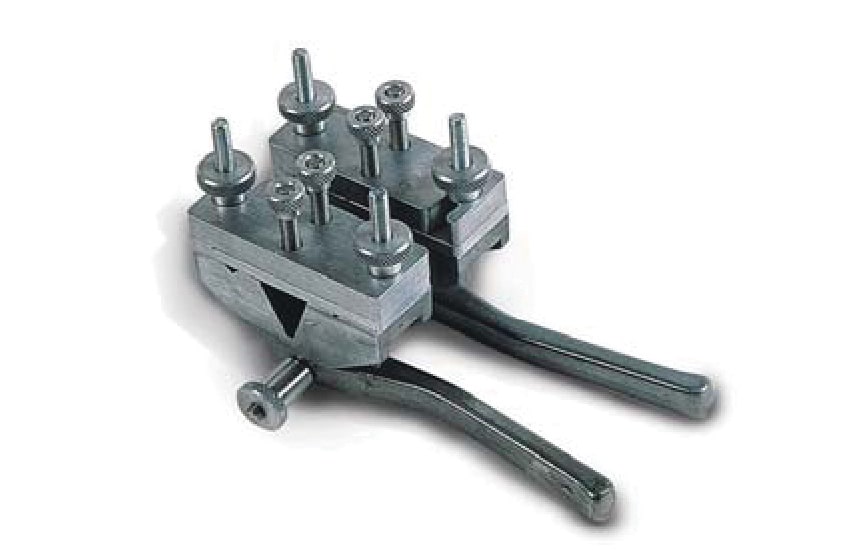

2サイズのハンドツールを使用することで、摩耗や破損したベルトストラップの交換時に機械の解体を不要にする。物流、段ボール、木材加工機械に最適で、ダウンタイムが高コストとなる場合に効果的である。

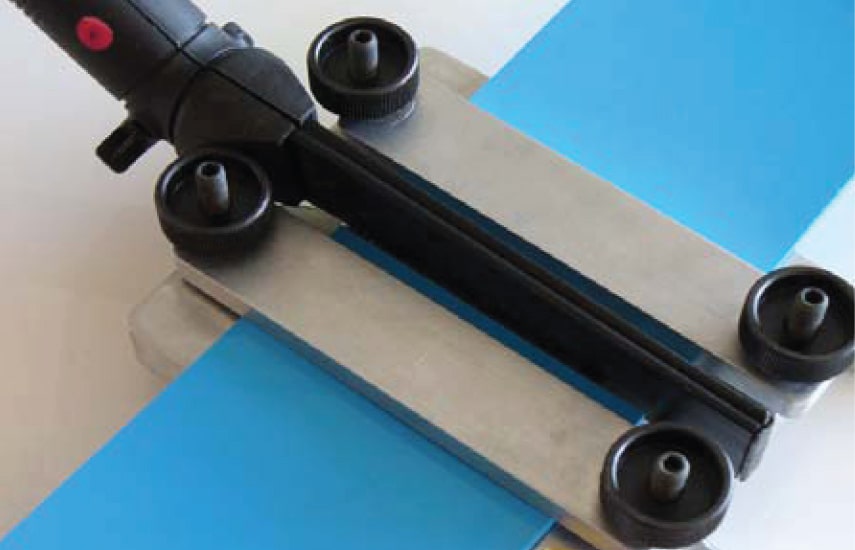

Voltaはプロファイルベルトの溶接用のハンドツールの範囲を製造している。バット溶接用と、より高い荷重に対応するための強化プロファイルや長い接合長に対応するオーバーラップ溶接システムのバージョンがある。

便利なリング溶接ジグは、リングの大量生産を容易にし、作業場の生産性とリングの長さの一貫性を向上させる。

Volta製のサイドウォールと組み合わせて使用される。Voltaのサイドウォールノズルを搭載した熱風ガンを保持するために設計されたトロリーは、狭い作業場でも最大100mmのサイドウォールの溶接を可能にする。

ノズルは、作業場での手動または半自動溶接装置を使用して、Vガイド、丸型プロファイルベルト、および電極を取り付けるために、熱風ガン用に用意されている。

この装置は、圧縮空気で操作するシンプルながら効果的なジグである。標準のスチールローラーは、Volta製の食品グレードTPUスリーブで迅速に被覆することができる。ベンチトップジグは工場の作業場に適しており、追加のローラーセットを在庫として保持する必要がなく、従来の方法で摩耗したセットを再生ゴムコーティングのために送る時間を節約できる。

Dough pump conveyors are used to process raw dough in large-scale production bakeries.

These conveyors elevate dough at a sharp incline and commonly use plied belts with bottom guides. Due to uneven loads, bakery belts often suffer from off-tracking, and slippage, which can cause fraying, tearing and the need for belt tension, leading to belt failure. A retrofit to

SuperDrive™ solves all of that, making raw dough production… as easy as pie.

When you are looking for the ideal solution to help you increase your production rate, simplify the process, slash costs and comply with regulations, it’s time for SuperDrive™!

A Positive Drive belt that solves the key mechanical problems of classic flat belts, namely, slipping and off-tracking, SuperDrive™ helps lower running costs for reduced cost of ownership, requires less hot water, provides less chemical exposure, and reduces cleaning time.

As a result, you have more time and money for production. Perfect!

Bakery lines often incorporate small pulley diameters and static ‘knife edge’ nose bars. When selecting the right belt for your business, make sure to measure the diameter/radius and, to note the wrapping angle.

Our bakery conveyor belts are specifically tailored for biscuit and pizza base cutting lines, helping make dough production simple and efficient.

Our TPE bakery conveyor belts are highly resistant to cuts and abrasion.

They are also easily repaired in the event of mechanical damage, making them robust, cost-effective, and literally, the best thing since sliced bread.

Ethical standards guide our business practices, reflecting our commitment to fairness, trust, and reliability. We value mutual respect, intellectual honesty, and humility.Each team member takes ownership of

their decisions and pursues continuous improvement. This philosophy builds enduring relationships that highlight our long-term success.

Despite our global reach, we maintain individuality in all interactions, cultivating strong relationships.

with customers, partners, and colleagues. Our approach ensures everyone feels valued and supported. We promote work-life balance through a family-oriented culture, creating an environment that fosters both individual and collective growth.

We encourage employees to take initiative, make decisions, and drive innovation by providing necessary resources. This culture of accountability enables our team to excel and contribute to the company’s progress. We nurture our employees’ potential through an inclusive environment, offering constructive feedback and recognition. Our commitment extends to self-actualization, helping staff find career fulfillment while advancing organizational goals.

Success at Volta is a collective endeavor. Our motto, “We are in it together; we will act as one,” embodies our commitment to unity and mutual support. We provide an environment of belonging and open communication. By harnessing each employee’s unique talents, we overcome challenges together as a team, making us stronger together than the sum of our parts.

Our stakeholders benefit from efficient, reliable, and high-performance belting products.

Our industry-leading expertise enables our customers and partners to stay ‘one step ahead’ while we support their sustainable growth. Our continuous investment in training and knowledge retention ensures innovative thinking and cutting-edge solutions designed to keep our customers at the forefront of their industries.

We prioritize our customers’ unique needs and challenges, offering tailored solutions to ensure their success. Our commitment drives continuous improvement of our products and services. We maintain a strategic Go-to-Market (GTM) mindset and a can-do approach, always aiming to innovate. Our emphasis on quality and customer-oriented solutions encourages mutual benefit and lasting partnerships.