Home » Positive Drive » SuperDrive™

SuperDrive™

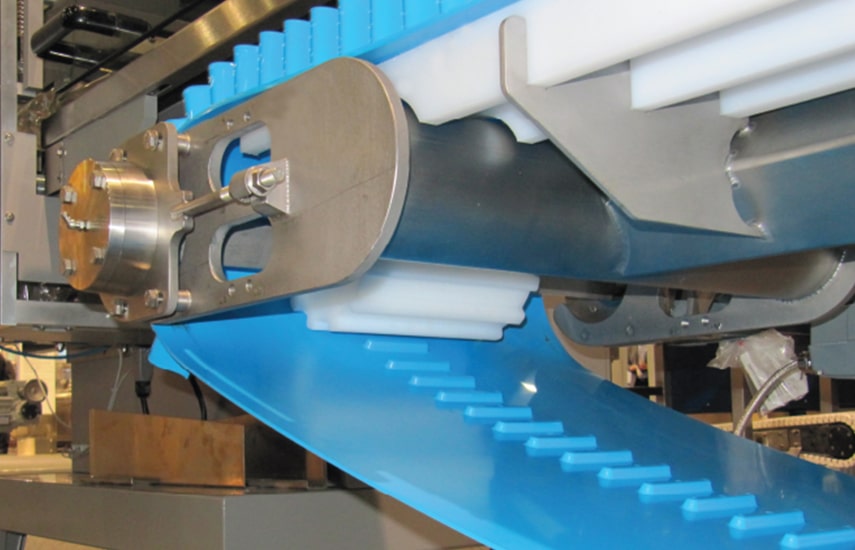

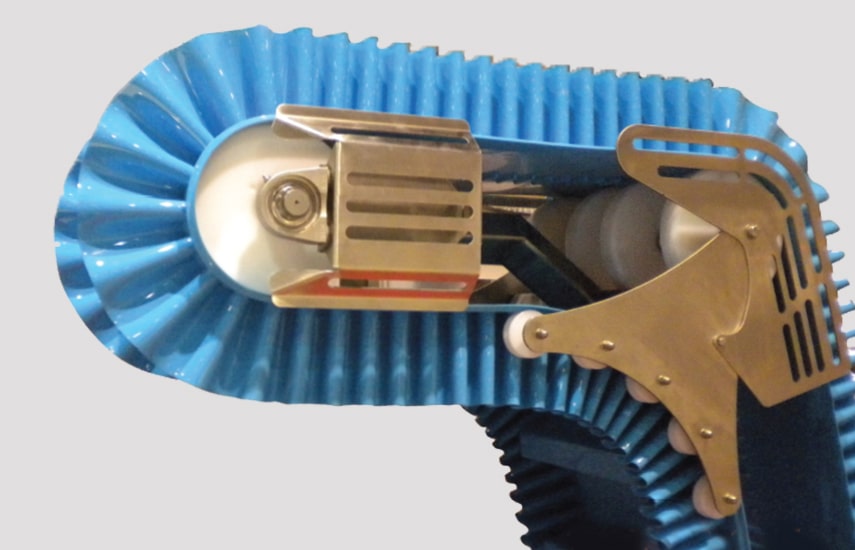

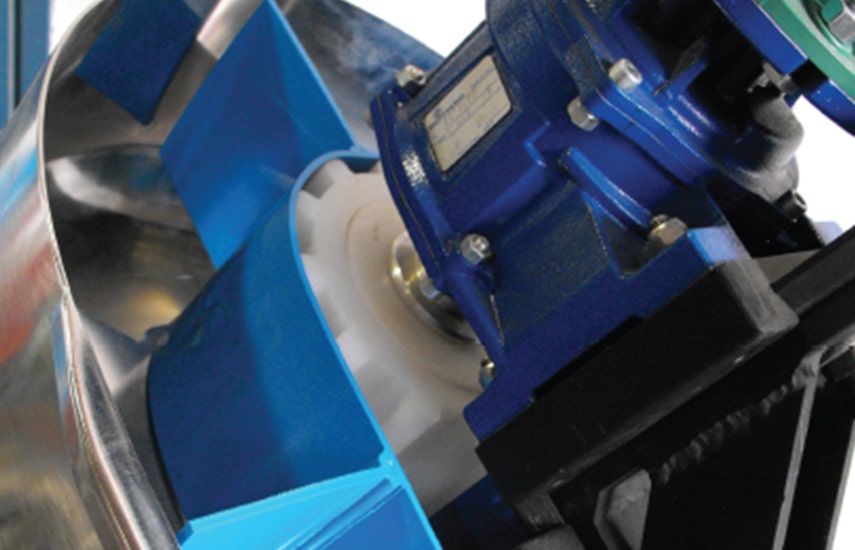

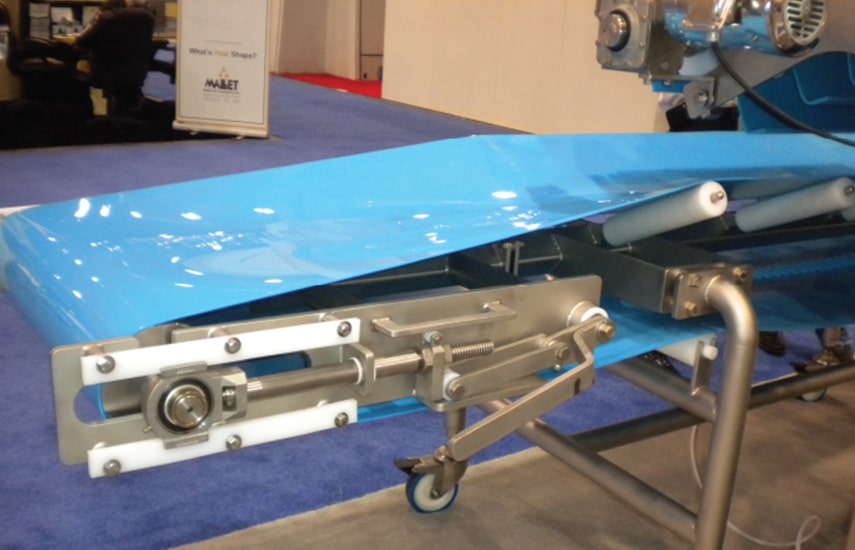

SuperDrive™ (SD) is a Positive Drive belt that solves the key mechanical problems of classic flat belts, namely, slipping and off-tracking.

Reduce running costs (reduced cost of ownership): less (hot) water, lower chemical exposure, reduced cleaning time, more time for production.

Material Features

Hygienic conveyor design

Superior

material quality

Reduces Amp draw on motors

Widest range of thermoplastic PD belts available

Non-standard fabrications and perforations

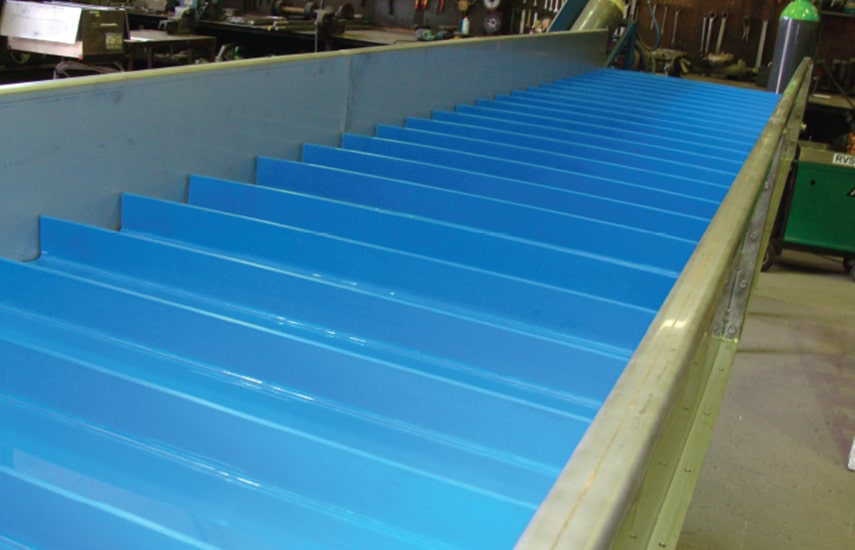

Suited to

trough conveyors

Advantages

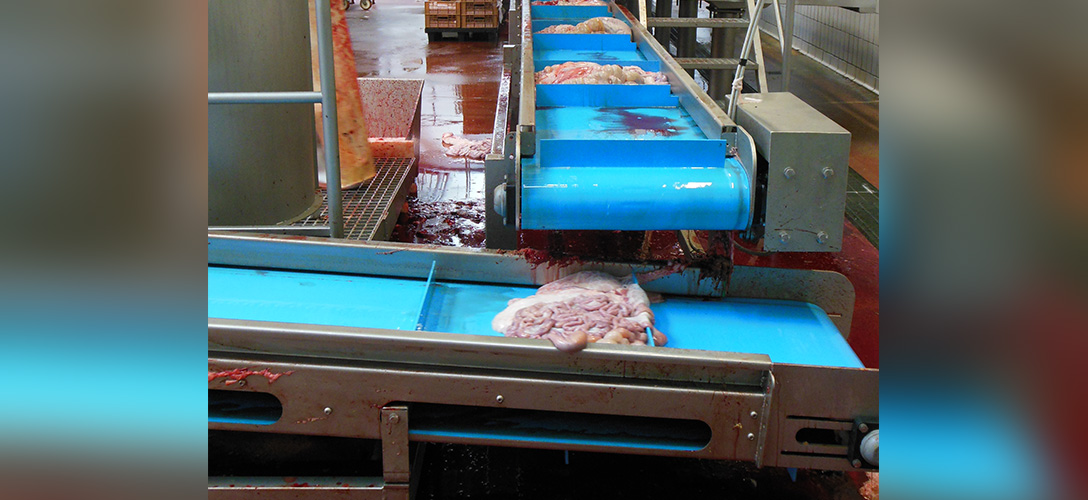

SuperDrive™ is manufactured from high performance, proprietary TPE/TPU materials in many finishes that enable it to be used in thousands of applications maintaining a pulley diameter at the 100mm range. Apart from the formidable mechanical advantages that SuperDrive™ offers, the most beneficial impact of the food grade range is seen in food processing where direct contact with food in all its stages of production raises hygienic concerns and exposes food to potential contamination.

High Risk Elements

Food processors are well-aware that conveyor belts and conveyor systems are high risk elements in the production line and the demand for food grade belts has led to a huge variety of belt types in the market. This complicates the belt choice for the processor who has specific requirements and must work efficiently and on a budget.

Hygienic Solution

Emerging guidelines often find it easier to describe what is not hygienic but there is agreement that homogenous belts are the most hygienic conveyor belt option. Together with the additional mechanical advantages of positive drive and self-tracking, it is the best choice for compact hygienic conveyors and for upgrading existing modular belt systems.

Mr. Wim Clazing from Exportslachterij Clazing BV, The Netherlands

Conveyors

Are you looking for a solution?

Learn from our experience

A multinational company with a chocolate factory located far from reliable belt service centers, called a Volta OEM partner in to review a long cocoa powder incline conveyor.

Fruit and Nut mixes are increasingly popular as a healthy alternative to other snacks. The sourcing of the varied products that go into mixes creates several problems

The fourth most important food crop worldwide is potatoes. 60% of the processing is handled in the most industrialized countries.

A newly equipped pork abattoir commissioned a set of conveyors designed with two flat belts that transferred offal at 90 degrees on a corner. The belts used synchronized compartments comprising of full width cleats, to keep each set of organs separate until the veterinary service on site had confirmed the meat as fit for consumption.