หน้าหลัก » Solutions By conveyor type » Elevators

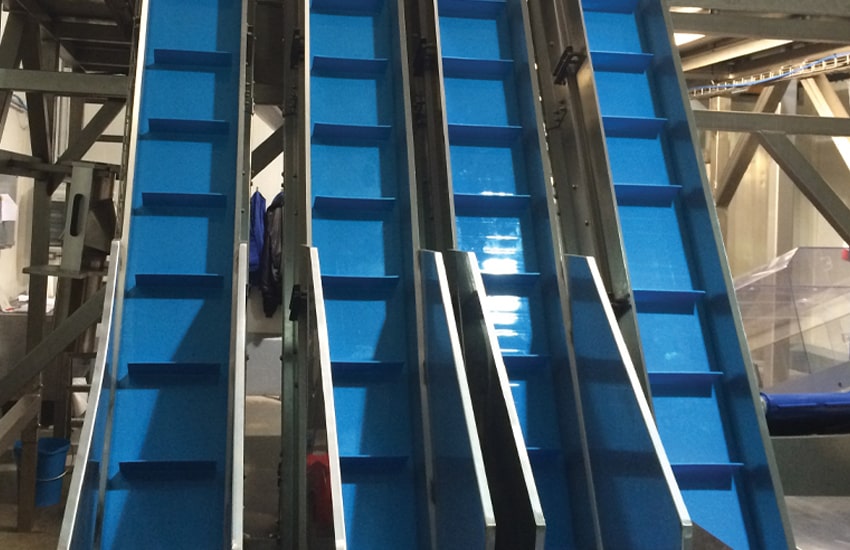

Elevators using cleated or sidewall conveyor belts are an accepted solution for transferring product from one height to another. They can be used for elevation or as declines to take a product down as in an IQ freezer outfeed. Elevators can have one inclined section or additional horizontal sections that require the belt to ‘transition’ from one orientation to another. Elevators can be simple two-axle conveyors or they can have one horizontal section (L-shaped) or two horizontal sections (Z, swan-neck, or goose-neck).

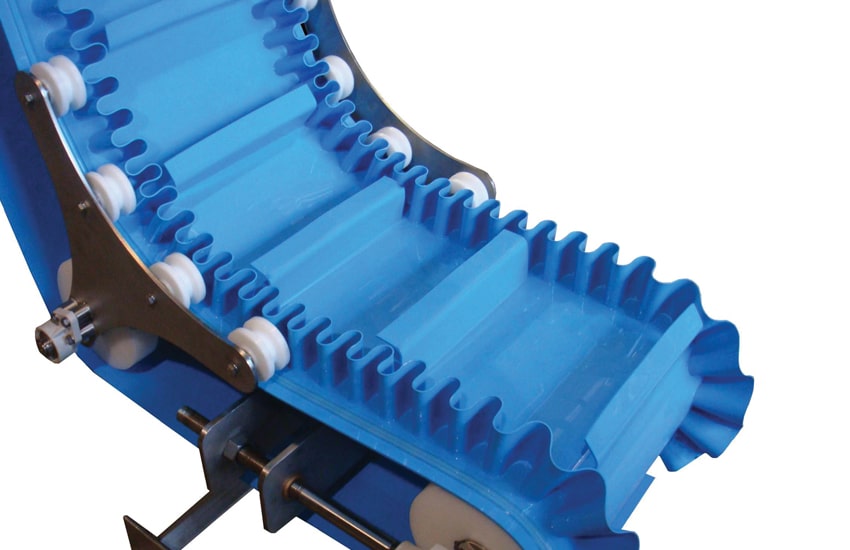

The transition areas are usually constructed in a reverse form on the belt return path and in the zone where the belt flexes around an arc on the work side, it back-flexes in the same zone underneath the conveyor. Correct design of these areas is critical to prevent belt failure. In addition, larger pulleys will be required to allow the belt to flex due to the addition of fabricated elements such as cleats, sidewalls, or top guides.

Volta’s service team helps designers and users understand and utilize these options as well as avoid mistakes in underestimating their impact on elevator design. Volta offers numerous options of cleat types that can handle and contain product even at severe angles. Perpendicular scoop-cleated belts in conjunction with Volta Positive Drive belts, replace modular and bucket elevator belts. The benefits of this combination minimize cleaning and maintenance, reduce motor output, lower noise levels, and reduce the overall cost of ownership.

When you are looking for the ideal solution to help you increase your production rate, simplify the process, slash costs and comply with regulations, it’s time for SuperDrive™!

A Positive Drive belt that solves the key mechanical problems of classic flat belts, namely, slipping and off-tracking, SuperDrive™ helps lower running costs for reduced cost of ownership, requires less hot water, provides less chemical exposure, and reduces cleaning time.

As a result, you have more time and money for production. Perfect!

Dough pump conveyors are used to process raw dough in large-scale production bakeries.

These conveyors elevate dough at a sharp incline and commonly use plied belts with bottom guides. Due to uneven loads, bakery belts often suffer from off-tracking, and slippage, which can cause fraying, tearing and the need for belt tension, leading to belt failure. A retrofit to

SuperDrive™ solves all of that, making raw dough production… as easy as pie.

Bakery lines often incorporate small pulley diameters and static ‘knife edge’ nose bars. When selecting the right belt for your business, make sure to measure the diameter/radius and, to note the wrapping angle.

Our bakery conveyor belts are specifically tailored for biscuit and pizza base cutting lines, helping make dough production simple and efficient.

Our TPE bakery conveyor belts are highly resistant to cuts and abrasion.

They are also easily repaired in the event of mechanical damage, making them robust, cost-effective, and literally, the best thing since sliced bread.