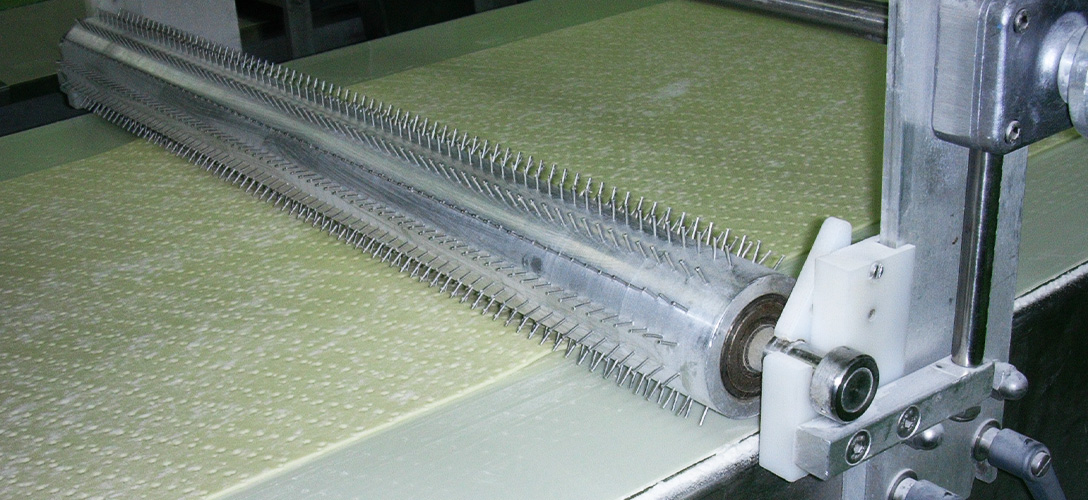

Cutting and docking processes have always been trouble spots where belt wear and tear is high. A secondary problem of concern in modern bakeries is the accumulation of bacteria in the cuts and fissures that develop before the belt fails. This type of deterioration in belt quality during its working life highlights the difference between mechanical lifetime and hygienic lifetime. While good mechanical lifetime is a gauge of success in non-hygienic applications, this cannot be used as a standard in food processing where the prime concern is hygiene. The main way to save cleaning and maintenance costs is by preventing contamination. Volta belts prevent this unhygienic wear and tear in bakery applications.

Volta Belts in Crackers & Bagels Production

The maintenance manager says: “Although a Volta belt is more expensive than the plied belt, at the end it turns out cheaper – because the cheap turned out to be expensive for us!”