TRANG CHỦ » Solutions By conveyor type » Profile Belt Conveyors

Volta profile belts are an integral part of numerous industrial applications such as conveying roof or ceramic tiles and activation “O” rings on live roller systems. Steel and aramid reinforced round belts are used in canning factories for aligning and transporting cans prior to filling.

In our case study of the ceramic and the roof tile industry, varied applications include high speed transfer of tiles or clay moulds, 90-degree curved corner conveyors, glazing lines, stacking machines, start/stop sorting operations as well as product handling in and around the oven.

Profile belts are used on a wide variety of fruit and vegetable grading systems as well as slicing machines. They handle delicate or flat product that would otherwise bounce up and down on flat belting. This includes laminated panels, sheet glass and wafers. Food grade round profile is commonly used on pizza topping re-claims and chocolate enrobing lines.

The packaging industry is a major user of round as well as soft grip top V belts. With the arrival of inhouse packaging machines in supermarkets for individual portions, a new thin T form profile was developed.

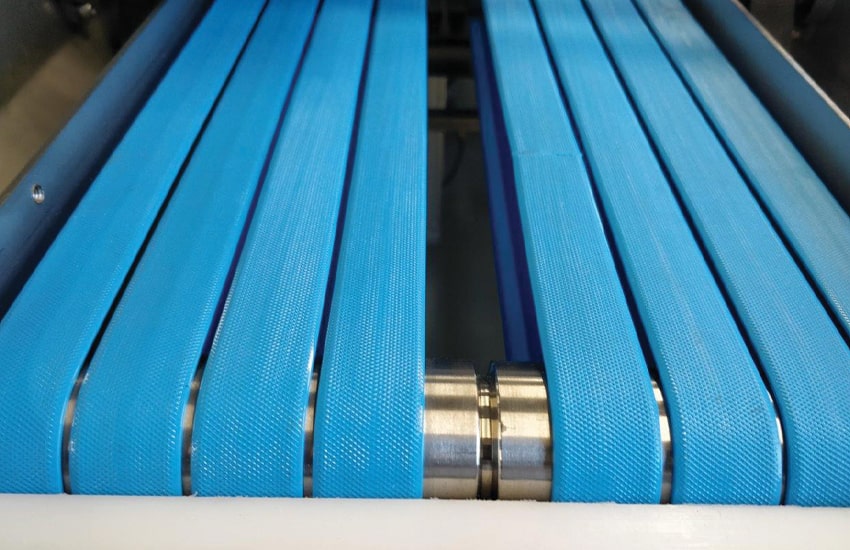

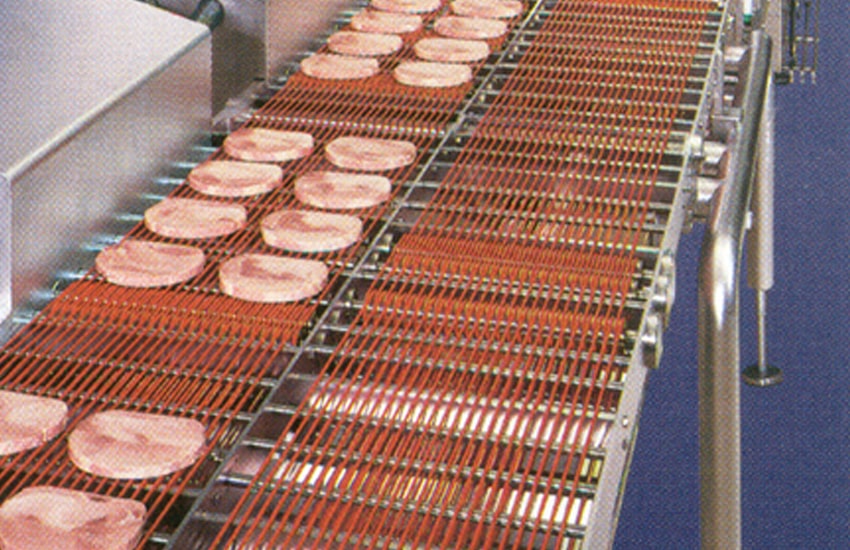

The profiles are not limited to V and Round shapes. Wider flat sections are finished in food grade material and are produced for transferring sausages in the meat processing industry. The sausage belts run in parallel V shape channels and flatten out at each end around the pulleys.

Hollow profiles are used on the top of chain drives. They are extruded with two different coloured layers for online wear detection.

Special flat sections with a delicate radius on the lead edges are extruded in a range of sizes made from an ink resistant TPE, designed for use in the printing industry.

There is an entire range of solid and cogged V belt styles manufactured from food grade materials that are used on Volta flat and Positive Drive belts as guides rather than stand-alone belts. Similarly, the mini-V profile called electrode is made for handmade welding operations and explained in detail on the fabrication page.

When you are looking for the ideal solution to help you increase your production rate, simplify the process, slash costs and comply with regulations, it’s time for SuperDrive™!

A Positive Drive belt that solves the key mechanical problems of classic flat belts, namely, slipping and off-tracking, SuperDrive™ helps lower running costs for reduced cost of ownership, requires less hot water, provides less chemical exposure, and reduces cleaning time.

As a result, you have more time and money for production. Perfect!

Dough pump conveyors are used to process raw dough in large-scale production bakeries.

These conveyors elevate dough at a sharp incline and commonly use plied belts with bottom guides. Due to uneven loads, bakery belts often suffer from off-tracking, and slippage, which can cause fraying, tearing and the need for belt tension, leading to belt failure. A retrofit to

SuperDrive™ solves all of that, making raw dough production… as easy as pie.

Bakery lines often incorporate small pulley diameters and static ‘knife edge’ nose bars. When selecting the right belt for your business, make sure to measure the diameter/radius and, to note the wrapping angle.

Our bakery conveyor belts are specifically tailored for biscuit and pizza base cutting lines, helping make dough production simple and efficient.

Our TPE bakery conveyor belts are highly resistant to cuts and abrasion.

They are also easily repaired in the event of mechanical damage, making them robust, cost-effective, and literally, the best thing since sliced bread.