Selecting the right conveyor belt for meat processing is a crucial decision that impacts food safety, product quality, and operational efficiency. With the industry’s demanding requirements, choosing the right food-grade, homogeneous belt is essential for minimizing risks and maximizing performance. Here are the top five best practices to consider when selecting a conveyor belt for the meat processing industry:

1. Hygiene and Contamination Prevention

In the meat processing industry, food safety begins with the design and materials of your conveyor system. Bacterial contamination is a constant concern, and selecting a belt that minimizes these risks is vital for the safety of the products and the facility. A food-grade belt should have the following characteristics to reduce contamination:

Consistent Quality and Durability: Homogeneous belts maintain their integrity under varying conditions, ensuring long-lasting performance.

No Exposed Fabric Edges: Exposed fabric edges or layers can trap dirt and bacteria. Choose a belt that has no such exposed surfaces, preventing the growth of harmful microorganisms.

Ease of Sanitation: The belt should be designed to withstand thorough cleaning without compromising its integrity.

Key Takeaway: The surface of the conveyor belt should actively resist bacterial growth and be easy to clean. This will reduce the risk of cross-contamination and support overall food safety.

2. Temperature and Environmental Resilience

Meat processing often involves extreme conditions that a standard conveyor belt might not withstand. Your chosen belt must operate flawlessly under:

Sub-zero Temperatures: Meat processing facilities can often operate in sub-zero environments, especially in freezing sections. The belt must remain flexible and durable at temperatures as low as -35°C.

Humidity and Moisture Exposure: Meat processing environments tend to be humid and wet, with frequent exposure to water, blood, and oils. The belt should resist degradation and brittleness under these conditions.

Chemical Exposure: Cleaning chemicals are commonly used in meat plants, and your belt must be resistant to chemical damage to ensure long-term performance.

Key Takeaway: A high-quality, food-grade conveyor belt should perform consistently across all temperature ranges and be resilient in the face of high humidity and exposure to chemicals and moisture.

3. Operational Durability and Performance

The meat processing environment can be tough on equipment. Conveyor belts must withstand heavy loads, sharp bone edges, abrasive interactions, and continuous mechanical stress. Key factors to consider include:

Precise Tracking Capabilities: A conveyor belt should maintain proper alignment during operation, even under heavy loads or when interacting with sharp objects.

Resistance to Slippage: Ensure the belt stays in position, even under the most demanding conditions.

Minimal Maintenance Requirements: A durable, high-performance belt should need minimal maintenance, reducing operational downtime and saving on replacement costs.

Key Takeaway: When selecting a conveyor belt, look for one that can handle the toughest physical demands of the meat processing industry while maintaining high performance and minimal maintenance requirements.

4. Cleaning and Maintenance Efficiency

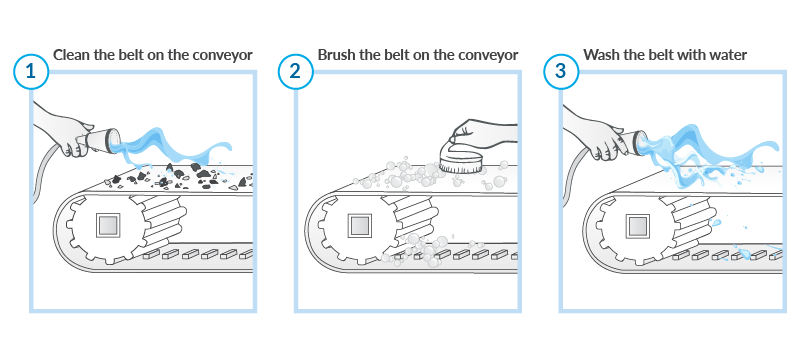

Efficient cleaning processes are essential in the meat processing industry. A conveyor belt that facilitates easy cleaning not only improves hygiene but also reduces downtime and operational costs. Key factors include:

On-Conveyor Cleaning: The belt should allow cleaning while still in operation, reducing the need for disassembly and downtime.

CIP (Clean-in-Place) Compatibility: The belt should be compatible with CIP solutions, ensuring quick and thorough cleaning without the need for manual intervention.

Water and Chemical Usage: Opt for a belt that reduces water consumption and minimizes the use of harsh cleaning chemicals

Key Takeaway: A well-designed belt should support efficient cleaning methods, ensuring that the system is sanitary with minimal downtime and resource usage.

5. Selecting the Right Homogeneous, Food-Grade Belt

When it comes to food-grade belts, homogeneous belts offer a significant advantage. These belts are made from a single material, with no fabric layers or seams, providing a smooth surface that resists contamination and bacteria growth. The key benefits of homogeneous belts include:

Consistent Quality and Durability: Homogeneous belts maintain their integrity under varying conditions, ensuring long-lasting performance.

Seamless Design: The lack of seams or fabric layers makes these belts easier to clean and reduces the chances of contamination.

Enhanced Hygiene: Homogeneous belts are less likely to harbor bacteria or residue, providing a safer solution for meat processing operations.

Key Takeaway: Homogeneous, food-grade belts are the ideal choice for the meat processing industry. Their seamless design, durability, and resistance to bacteria make them the top pick for maintaining high hygiene standards and optimal performance.

Volta Belting: The Right Choice for Meat Processing

When looking for the ideal food-grade, homogeneous conveyor belt for your meat processing needs, Volta Belting is a leader in the industry. Known for its high-quality belts that combine performance with hygiene, Volta offers a wide range of conveyor belts specifically designed to meet the tough demands of meat processing facilities.

Our belts are designed to provide superior durability, ease of cleaning, and resistance to bacteria, ensuring that your production line runs smoothly and safely.

With Volta Belting’s innovative solutions, you can be confident that your belt system will enhance both the efficiency and safety of your meat processing operations.

Choosing the right conveyor belt for your meat processing operation is a vital decision that impacts food safety, product quality, and productivity.

By following these top 5 practices and opting for a homogeneous, food-grade belt like those offered by Volta Belting, you can ensure that your facility remains compliant with food safety standards while operating at peak efficiency.

For more information, please contact our experts today!